The bypass filtration units manufactured by our company are mobile devices. They are designed for filtering oils in machines and devices of various types (turbine lubrication systems, presses, plastic injection moulding machines, compressors, etc.).

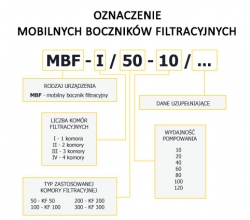

They are manufactured as a series of types:

Mobile bypass filtration unit MBF-I/50-10 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-I/50-10 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up,

- oil pumping out with the filtration chamber bypassed.

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Technical parameters of the device:

- nominal pumping capacity: 10l/min

- recommended volumes of cleaned systems: ≤ 1000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 360,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 3,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 230V, 400V

- supply power frequency 50Hz

- electric motor rated power: 0,37kW

- electric motor speed: 1360 obr/min

- weight: 18kg

- overall dimensions: 600x320x590mm

- functions: filtering, pressure pumping

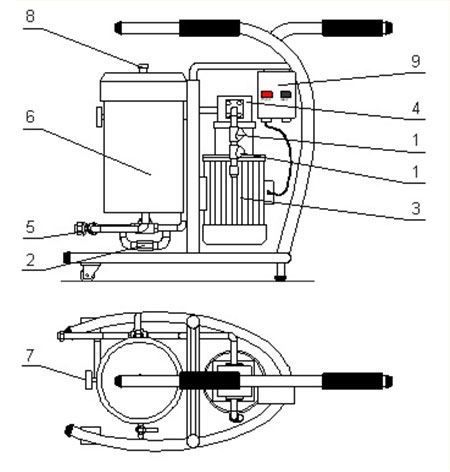

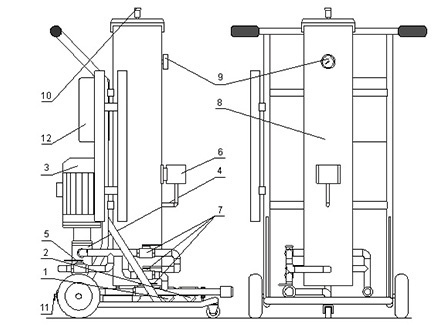

1. Mesh filter

2. Check valve

3. Electric motor

4. Gear pump

5. Adjustment valve

6. Nonwoven fabric filter (in the filtration chamber)

7. Manometer (quantitative filter contamination indicator)

8. Indpection / drainage plug

9. Electic box

The filter elements used:

The following filter elements can be used in MBF-I/50-10 device:

- WF-W-200/01-225/97

- WF-W-200/03-225/97

- WF-W-400/05-225/97

- WF-W-400/10-225/97

- WF-W-400/25-225/97

Mobile bypass filtration unit MBF-I/100-10 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-I/100-10 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up,

- oil pumping out with the filtration chamber bypassed.

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices,

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Technical parameters of the device:

- nominal pumping capacity: 10l/min

- recommended volumes of cleaned systems: ≤ 1000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 220,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 2,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 230V,

- supply power frequency 50Hz

- electric motor rated power: 0,55kW

- electric motor speed: 1350 obr/min

- weight: 35kg

- overall dimensions: 600x320x590mm

- functions: filtering, pressure pumping

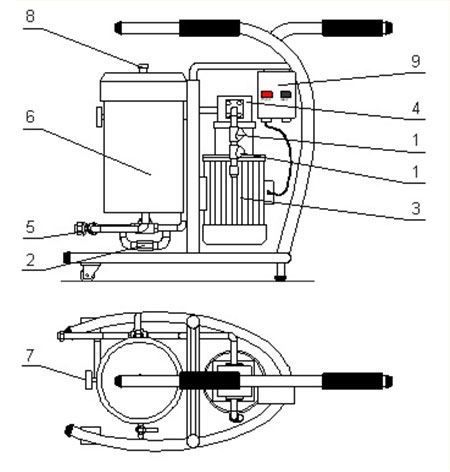

1. Mesh filter

2. Check valve

3. Mesh filter

4. Electric motor

5. Gear pump

6. Adjustment valve

7. Nonwoven fabric filter (in the filtration chamber)

8. Manometer (quantitative filter contamination indicator)

9. Automatic air vent

The filter elements used:

The following filter elements can be used in MBF-I/100-10 device:

- WF-W-200/01-255/145

- WF-W-200/03-255/145

- WF-W-400/05-255/145

- WF-W-400/10-255/145

- WF-W-400/25-255/145

Mobile bypass filtration unit MBF-I/200-20 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-I/200-20 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up,

- oil pumping out with the filtration chamber bypassed.

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices,

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Technical parameters of the device:

- nominal pumping capacity: 20l/min

- recommended volumes of cleaned systems: ≤ 2000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 680,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 2,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 400V,

- supply power frequency 50Hz

- electric motor rated power: 1,1kW

- electric motor speed: 1380 obr/min

- weight: 55kg

- overall dimensions: 650x650x1100mm

- functions: filtering, pressure pumping

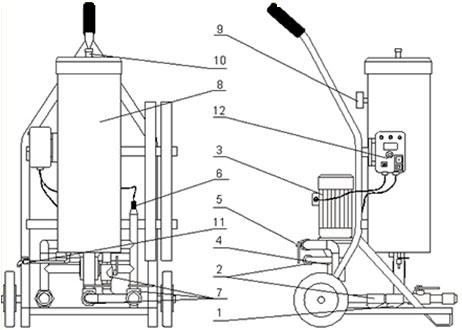

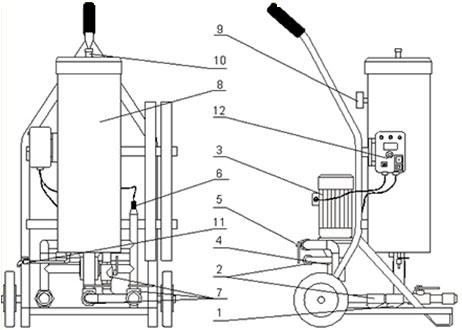

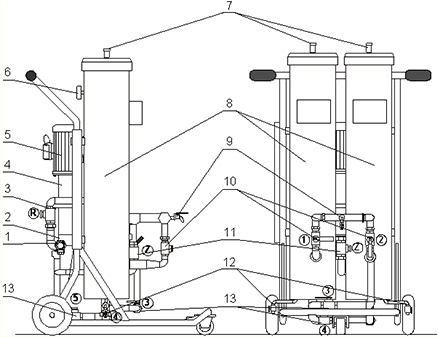

1. Mesh filter

2. Check valve

3. Electric motor

4. Gear pump

5. Adjustment valve

6. Pressure switch

7. Cut-off valve

8. Nonwoven fabric filter (in the filtration chamber)

9. Manometer (quantitative filter contamination indicator)

10. Automatic air vent

11. Inspection / drainage plug

12. Electric box

The filter elements used:

The following filter elements can be used in MBF-I/200-20 device:

- WF-W-200/01-470/145

- WF-W-200/03-470/145

- WF-W-400/05-470/145

- WF-W-400/10-470/145

- WF-W-400/25-470/145

Mobile bypass filtration unitMBF-I/200-40 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-I/200-40 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up,

- oil pumping out with the filtration chamber bypassed

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions,

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different

Technical parameters of the device:

- nominal pumping capacity: 40l/min

- recommended volumes of cleaned systems: ≤ 4000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 220,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 3,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 400V,

- supply power frequency 50Hz

- electric motor rated power: 1,1kW

- electric motor speed: 1380 obr/min

- weight: 55kg

- overall dimensions: 650x650x1100mm

- functions: filtering, pressure pumping

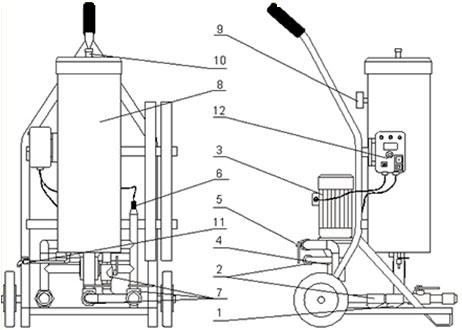

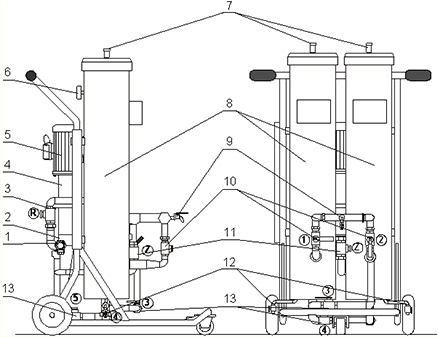

1. Mesh filter

2. Check valve

3. Electric motor

4. Gear pump

5. Adjustment valve

6. Pressure switch

7. Cut-off valve

8. Nonwoven fabric filter (in the filtration chamber)

9. Manometer (quantitative filter contamination indicator)

10. Automatic air vent

11. Inspection / drainage plug

12. Electric box

The filter elements used:

The following filter elements can be used in MBF-I/200-20 device:

- WF-W-200/01-470/145

- WF-W-200/03-470/145

- WF-W-400/05-470/145

- WF-W-400/10-470/145

- WF-W-400/25-470/145

Mobile bypass filtration unit MBF-I/200-60 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-I/200-60 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up,

- oil pumping out with the filtration chamber bypassed

Urządzenie należy stosować:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Technical parameters of the device:

- nominal pumping capacity: 60l/min

- recommended volumes of cleaned systems: ≤ 6000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 220,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 3,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 400V,

- supply power frequency 50Hz

- electric motor rated power: 1,1kW

- electric motor speed: 1380 obr/min

- weight: 55kg

- overall dimensions: 650x650x1100mm

- functions: filtering, pressure pumping

1. Mesh filter

2. Check valve

3. Electric motor

4. Gear pump

5. Adjustment valve

6. Pressure switch

7. Cut-off valve

8. Nonwoven fabric filter (in the filtration chamber)

9. Manometer (quantitative filter contamination indicator)

10. Automatic air vent

11. Inspection / drainage plug

12. Electric box

The filter elements used:

The following filter elements can be used in MBF-I/200-60 device:

- WF-W-200/01-470/145

- WF-W-200/03-470/145

- WF-W-400/05-470/145

- WF-W-400/10-470/145

- WF-W-400/25-470/145

Mobile bypass filtration unit MBF-I/300-60 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed

Design and structure of the mobile bypass filtration unit MBF-I/300-60 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up

- oil pumping out with the filtration chamber bypassed.

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Parametry techniczne urządzenia

- nominal pumping capacity: 60l/min

- recommended volumes of cleaned systems: ≤ 6000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 220,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 3,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 400V,

- supply power frequency 50Hz

- electric motor rated power: 1,1kW

- electric motor speed: 1415 obr/min

- weight: 120kg

- overall dimensions: 650x750x1280mm

- functions: filtering, pressure pumping

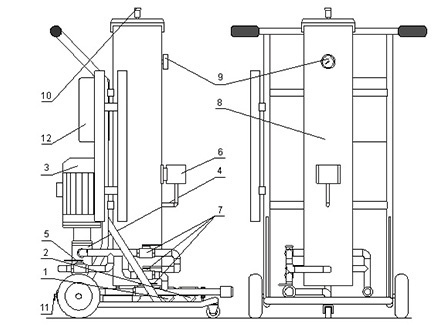

1. Check valve

2. Mesh filter

3. Electric motor

4. Screw pump

5. Adjustment valve

6. Pressure switch

7. Cut-off valve

8. Nonwoven fabric filter (in the filtration chamber)

9. Manometer (quantitative filter contamination indicator)

10. Automatic air vent

11. Chamber drainage vale

12. Electric box

The filter elements used:

The following filter elements can be used inMBF-I/300-60 device:

- WF-W-200/01-920/145

- WF-W-200/03-920/145

- WF-W-400/05-920/145

- WF-W-400/10-920/145

- WF-W-400/25-920/145

Mobile bypass filtration unit MBF-I/300-80 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-I/300-80 allows to use it in three different variants:

- oils system by-pass filtration (off-line),

- filtering-assisted oil system topping up,

- oil pumping out with the filtration chamber bypassed

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions,

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices,

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Technical parameters of the device

- nominal pumping capacity: 80l/min

- recommended volumes of cleaned systems: ≤ 6000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 220,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 3,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 400V,

- supply power frequency 50Hz

- electric motor rated power: 1,5kW

- electric motor speed: 1415 obr/min

- weight: 120kg

- overall dimensions: 650x750x1280mm

- functions: filtering, pressure pumping

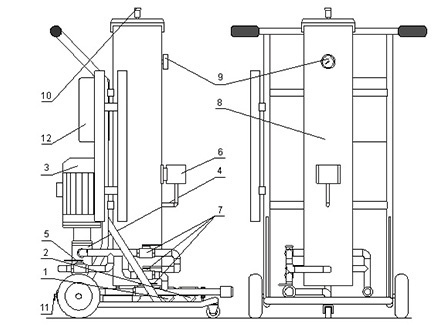

1. Check valve

2. Mesh filter

3. Electric motor

4. Screw pump

5. Adjustment valve

6. Pressure switch

7. Cut-off valve

8. Nonwoven fabric filter (in the filtration chamber)

9. Manometer (quantitative filter contamination indicator)

10. Automatic air vent

11. Chamber drainage vale

12. Electric box

The filter elements used:

The following filter elements can be used inMBF-I/300-60 device:

- WF-W-200/01-920/145

- WF-W-200/03-920/145

- WF-W-400/05-920/145

- WF-W-400/10-920/145

- WF-W-400/25-920/145

Mobile bypass filtration unit MBF-II/200-40 is a device designed to removing mechanical impurities from oils used in turbines, compressors, transmissions, hydraulic power systems etc. It can be used also for filtering-assisted refilling or removing (pumping out) oils with the filtration chamber of the system being bypassed.

Design and structure of the mobile bypass filtration unit MBF-II/200-40 allows to use it in three different variants:

- oils system by-pass filtration (off-line)

- filtering-assisted oil system topping up

- oil pumping out with the filtration chamber bypassed.

The unit should be used as:

- as an independent device filtering oil in lubrication systems of machines and devices operated continuously in special conditions

- in case of newly purchased fresh oils, for oil filtering when refilling oil systems of machines and devices

- as an oil-pumping device with the filtration chamber bypassed (e.g. for spent oils)

Mobile bypass filtration units can be manufactured against individual customer orders. In vie of that, the type an configuration of subassemblies mounted in them can be different.

Technical parameters

- nominal pumping capacity: 40l/min

- recommended volumes of cleaned systems: ≤ 6000

- filtered liquid kinematic viscosity coefficient range: 2,0 .. 220,0 mm2/s

- operating temperature range: 0 .. +80

- the maximum filter operating range — pressure: 3,0 bar

- minimum pressure at inlet: -0,05 MPa

- supply power voltage: 380V,

- supply power frequency 50Hz

- electric motor rated power: 2,2kW

- electric motor speed: 1420 obr/min

- weight: 120kg

- overall dimensions: 650x750x1100mm

- functions: filtering, pressure pumping

1. Mesh filter

2. Check valve

3. Electric motor

4. Gear pump

5. Adjustment valve

6. Pressure switch

7. Cut-off valve

8. Nonwoven fabric filter (in the filtration chamber)

9. Manometer (quantitative filter contamination indicator)

10. Automatic air vent

11. Inspection/drainage plug

The filter elements used:

The following filter elements can be used in MBF-II/200-40 device:

- WF-W-200/01-470/145

- WF-W-200/03-470/145

- WF-W-400/05-470/145

- WF-W-400/10-470/145

- WF-W-400/25-470/145

Mobilny bocznik filtracyjny MBF-II/300-100 jest urządzeniem przeznaczonym do usuwania z olejów (turbinowych, sprężarkowych, przekładniowych, hydraulicznych i innych) zanieczyszczeń mechanicznych. Może także służyć do uzupełniania filtracyjnego lub usuwania – wypompowywania z pominięciem komory filtracyjnej oleju w układzie, przy którym pracuje.

Budowa i konstrukcja bocznika filtracyjnego MBF-II/300-100 umożliwia pracę w trzech różnych wariantach:

- filtrowanie bocznikowe układu olejowego (off – line),

- uzupełnianie filtracyjne układu olejowego,

- wypompowywanie oleju z pominięciem komory filtracyjnej.

Urządzenie należy stosować:

- do olejów świeżo zakupionych, filtrując olej podczas napełniania systemów olejowych urządzeń

- jako urządzenie niezależnie filtrujące olej w układach urządzeń i maszyn pracujących w ruchu ciągłym w specjalnych warunkach,

- jako urządzenie pompujące oleje z pominięciem komory filtracyjnej olejów przepracowanych.

Mobilny bocznik filtracyjny może być wykonane na indywidualne potrzeby odbiorcy. W związku z tym konfiguracja i rodzaj zamontowanych urządzeń może być różna.

Parametry techniczne urządzenia

- nominalne wydajności pompowania: 40l/min

- zalecane pojemności oczyszczanych układów: ≤ 6000

- zakres lepkości kinematycznej filtrowanej cieczy: 2,0 .. 220,0 mm2/s

- zakres temperatury pracy: 0 .. +80

- maksymalny zakres pracy filtra – ciśnienie: 3,0 bar

- minimalne ciśnienie na wejściu: -0,05 MPa

- napięcie zasilania: 380V

- częstotliwość napięcia zasilającego 50Hz

- moc silnika: 2,2kW

- prędkość obrotowa silnika: 1420 obr/min

- masa: 120kg

- wymiary gabarytowe: 650x750x1100mm

- funkcje: filtrowanie, przetłaczanie

1. Filtr siatkowy

2. Zawór zwrotny

3. Silnik elektryczny

4. Pompa śrubowa

5. Zawór regulacyjny

6. Wyłącznik ciśnieniowy

7. Zawór odcinający

8. Filtr włókninowy (komora filtracyjna)

9. Manomert (ilościowy wskaźnik zanieczyszczenia filtra)

10. Autommatyczne odpowietrzanie układu

11. Rewizyjny zawór spustowy

12. Zawór bezpieczeństwa

13. Skrzynka elektryczna

Stosowane wkłady filtracyjne:

W urządzeniu typu MBF-II/300-100 można stosować następujące wkłady filtracyjne:

- WF-W-200/01-920/145

- WF-W-200/03-920/145

- WF-W-400/05-920/145

- WF-W-400/10-920/145

- WF-W-400/25-920/145

W każdym z tych typów agregatów instaluje się 2 wkłady filtracyjne (ten typ agregatu posiada 2 pracujące równolegle komory filtracyjne).

Mobilny bocznik filtracyjny MBF-II/300-120 jest urządzeniem przeznaczonym do usuwania z olejów (turbinowych, sprężarkowych, przekładniowych, hydraulicznych i innych) zanieczyszczeń mechanicznych. Może także służyć do uzupełniania filtracyjnego lub usuwania – wypompowywania z pominięciem komory filtracyjnej oleju w układzie, przy którym pracuje.

Budowa i konstrukcja bocznika filtracyjnego MBF-II/300-120 umożliwia pracę w trzech różnych wariantach:

- filtrowanie bocznikowe układu olejowego (off – line),

- uzupełnianie filtracyjne układu olejowego,

- wypompowywanie oleju z pominięciem komory filtracyjnej.

Urządzenie należy stosować:

- do olejów świeżo zakupionych, filtrując olej podczas napełniania systemów olejowych urządzeń

- jako urządzenie niezależnie filtrujące olej w układach urządzeń i maszyn pracujących w ruchu ciągłym w specjalnych warunkach,

- jako urządzenie pompujące oleje z pominięciem komory filtracyjnej olejów przepracowanych.

Mobilny bocznik filtracyjny może być wykonane na indywidualne potrzeby odbiorcy. W związku z tym konfiguracja i rodzaj zamontowanych urządzeń może być różna.

Parametry techniczne urządzenia

- nominalne wydajności pompowania: 120l/min

- zalecane pojemności oczyszczanych układów: ≤ 12000

- zakres lepkości kinematycznej filtrowanej cieczy: 2,0 .. 220,0 mm2/s

- zakres temperatury pracy: 0 .. +80

- maksymalny zakres pracy filtra – ciśnienie: 3,0 bar

- minimalne ciśnienie na wejściu: -0,05 MPa

- napięcie zasilania: 400V

- częstotliwość napięcia zasilającego 50Hz

- moc silnika: 3~2,2kW

- prędkość obrotowa silnika: 2820 obr/min

- masa: 155kg

- wymiary gabarytowe: 880x910x1400mm

- funkcje: filtrowanie, przetłaczanie

1. Filtr siatkowy

2. Zawór zwrotny

3. Silnik elektryczny

4. Pompa śrubowa

5. Zawór regulacyjny

6. Wyłącznik ciśnieniowy

7. Zawór odcinający

8. Filtr włókninowy (komora filtracyjna)

9. Manomert (ilościowy wskaźnik zanieczyszczenia filtra)

10. Autommatyczne odpowietrzanie układu

11. Rewizyjny zawór spustowy

12. Zawór bezpieczeństwa

13. Skrzynka elektryczna

Stosowane wkłady filtracyjne:

W urządzeniu typu MBF-II/300-120 można stosować następujące wkłady filtracyjne:

- WF-W-200/01-920/145

- WF-W-200/03-920/145

- WF-W-400/05-920/145

- WF-W-400/10-920/145

- WF-W-400/25-920/145

W każdym z tych typów agregatów instaluje się 2 wkłady filtracyjne (ten typ agregatu posiada 2 pracujące równolegle komory filtracyjne).

- The unit can be configured and equipped as per the customer needs. We can also manufacture the unit according to explosion-proof standards.

- Filtration units allow to carry out the following operations:

- bypass oil cleaning in the course of regular machine operation

- pumping used oil out of machines with the filtration chamber bypassed

- zalewanie układów olejowych świeżym olejem

- A specially designed union piece of the bypass filtering unit allows to connect easily and flexibly to different oil reservoirs via their oil refills plug without machine stoppage. At the same time, it secures correct relative position of suction and pressure hose tips.

- Our devices guarantee operational cleanliness of machine oil systems consistent with requirements of ISO standards.

- Detailed technical specifications of mobile bypass filtration units together with dimensioned drawings can be found in the download section.